R&D

SWECO is continuously researching and developing the next-generation of insulation technologies to provide the maximum quality that our customers expect.

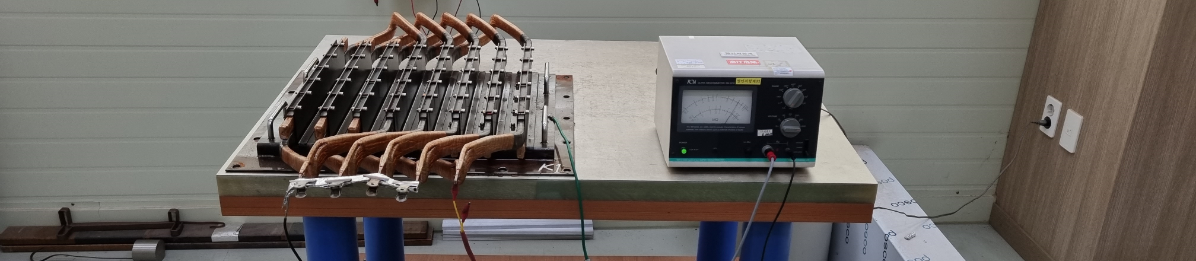

Laboratory Test Equipment

Insulation diagnosis Tester

Tanδ-voltage test, AC current test, partial discharge test, Tanδ-temperature test

Test voltage

AC 1kV~30kV Test sample size: 0.1nF~10µF (GST mode)

Ultra AC Dieletric Tester

KSC IEC 60034-18-32 Electrical durability evaluation tests

Test voltage

30kV 1A, 60kV 500mA, 125kV 264mA

The types of tests

B.D.V Test, Voltager Endurance Test

VPI Tank for Laboratory

Vacuum/pressure impregnator for making the model coils for tests

Vacuum/pressure impregnator for laboratories equipment

VACUUM: 0.2tor, pressurized mode : 100psi

Impregnating resins

Epoxy, silicone, and other VPI resins

Large Oven for Thermal Aging

KSC IEC 60034-18-31 Thermal evaluation test for the insulation system

Temperature range for the test

300˚C or below (3-phase 220V 24kW)

Size(inner)

800X1600X800

Large Oven for High Voltage and Temperature

KSC IEC 60034-18-32 Electrical durability evaluation tests

KSC IEC 60034-18-33 Composite Thermal & Electrical Durability Evaluation tests

Temperature range for the test

300˚C or below (3-phase 220V 00kW)

Size (inner)

800X1600X800

Differential Scanning Calorimetry

Fire Resistance Tester

In a test environment that requires using a regulated flame to maintain its temperature at 750℃ or higher, this tester evaluates the cables whose circuit integrity must be maintained when exposed to the flame under test conditions.

Includes fireproof, spray, and strike(ex. BS 6387 C, W, Z)

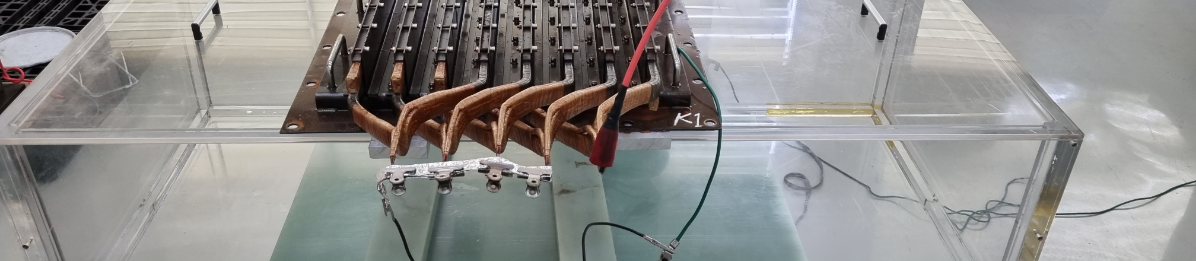

B.D.V Tester after U Banding

Coil Test List

Conductors Insulation Test

- B.D.V Test after U Banding

- B.D.V Test for Conductors after Forming

- B.D.V Test for Conductors after Curing

Initial Chraracteristic Test of Coil

- Impregnation Test of Model Coil

- Resin Drop Qty Measurement When Curing

- Tanδ- Temperature Test

- Tanδ Temperature Test under High Temperature

- Over Voltage Life Cycle Test

- Distortion Rate Test of Insulation Surface

- Electrical Characteristic Test

- Insulation Resistance.P.I. Test

- AC Current Test

- Tanδ- Voltage Test

- N-Q Characteristic Test (P-D Test)

- V-Q Characteristic Test (P-D Test)

- B.D.V Test

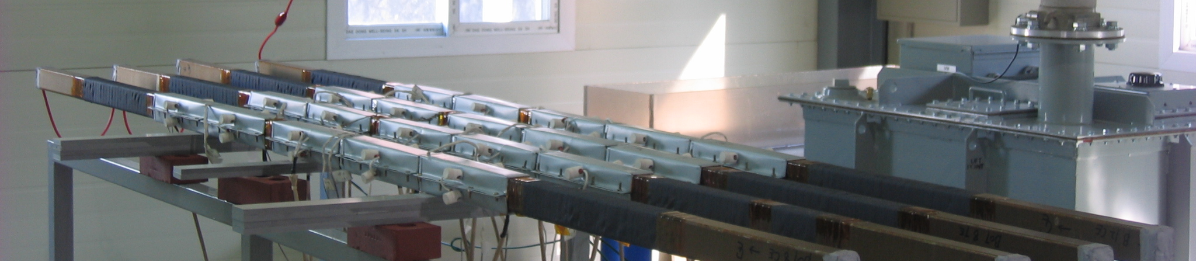

Thermal Endurance Evaluation

- KSC IEC 60034-18-1 General Guidelines for the Functional Evaluation of the Insulation Systems

- KSC IEC 60034-18-31 Evaluation Tests for Thermal Durability

- KSC IEC 60216-1,2,3 Guidelines for the Determination of the Heat Resistance of Electrical Insulation Materials

- KSC IEC 60493-1 Guidelines for the Statistical Analysis of the Aging Test Data

Voltage Endurance Evaluation

- KSC IEC 60034-18-1 General Guidelines for the Functional Evaluation of the Insulation Systems

- KSC IEC 60034-18-32 Evaluation Tests for Electrical Durability

- IEC 62539 Guidelines for the Statistical Analysis of the Electrical Insulation Breakdown Data

Multifactor Endurance Evaluation

- KSC IEC 60034-18-1 General Guidelines for the Functional Evaluation of the Insulation Systems

- KSC IEC 60034-18-33 An Evaluation Test for Thermal & Electrical Composite Durability

Thermal Cycling Evaluation

- IEEE Std 1310 The Thermal Cycle Test of the Stator Bars and Coils for Large Rotating Machines